Laser Marking and Engraving Machinery What Is It? How Is It Used? Types Of

1. Lasers What is a Laser? Laser is an acronym for "Light Ampli cation by Stimulated Emission of Radiation." Laser Characteristics Lasers differ from other light sources (such as the sun, incandescent or Ordinary light Laser beam Wave length Wave length 1. High Monochromaticity

Basic Laser Part Marking EDMtechcenter

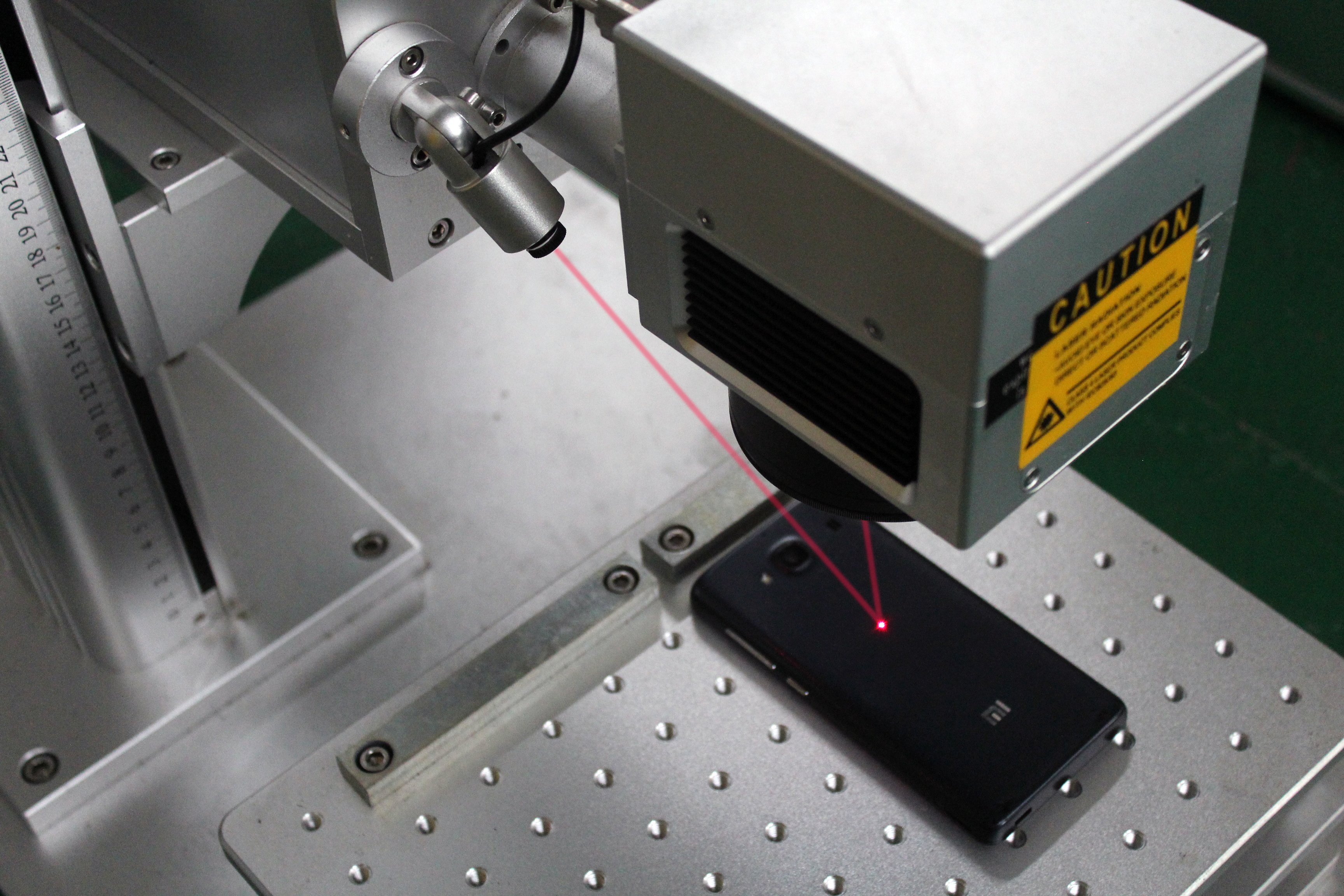

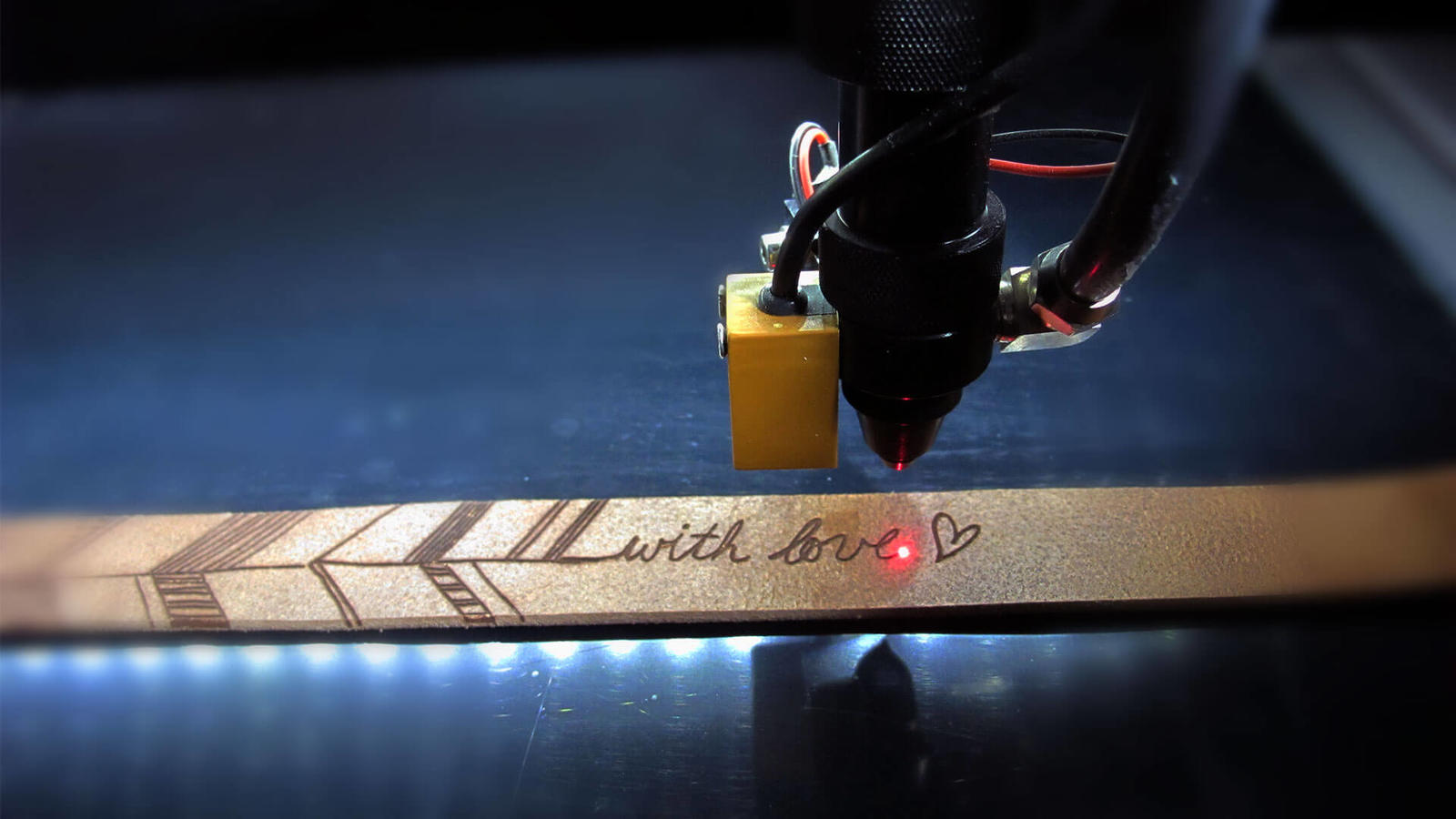

Laser marking is a fast and flexible process that can mark alphanumerics, graphics, logos, barcodes and bitmaps. Compared with other marking technologies such as inkjet printing and mechanical marking, laser marking has a number of advantages. It offers very high processing speeds, low operational costs and consistent high quality and dura-

Laser Marking Annealing Medical Device & Implants

Laser marking technology provides a method for permanently applying 2D matrix codes to most commonly used board substrates and conformal coatings. The high-resolution and high-accuracy of beam-steered laser marking systems provides the means to create well-defined codes for high-reliability reading regardless of code size.

How Laser Engraving Technology Is Revolutionizing The Manufacturing

Download What are Visible Rays? Some electromagnetic waves fall within the range of wavelengths that can be seen by humans. These are called visible rays. On the short wavelength side, visible rays measure from 360 to 400 nm. On the long wavelength side, they measure from 760 to 830 nm.

Laser Marking Systems for Industrial Tags and Labels TYKMA Electrox

Color laser marking has been known for a long time, so, many researches have been conducted about using different kinds of laser sources, effects of environmental conditions on the results and analysis of physical and chemical properties of the surfaces before and after laser treatment.

Laser marking

rect UDI product marking is the laser marking method, also r e- ferred to as laser annealing [5, 6]. is method is established as the industry standard marking method for medical devices.

Standard Laser Marking Machines Standard Laser Marking Systems

Handbook for Engravers www.troteclaser.com Tips & Tricks for working with the laser Contents 3 Introduction 3 What can a laser do? 4 Laser sources and available options 4 CO2 and fiber lasers 4 flexx function 5 From concept to finished workpiece 6 How does the laser work? 6 Process: Vector interface 6 Process: Raster engraving

Laser Marking Amada Miyachi

If a marking laser is used in joining preparation, it can also apply a Data Matrix Code or serial number to the component simultaneously. This takes care of both cleaning and traceability in a single step. At a glance — the advantages of using a marking laser as a complementary tool in joining processes:

Laser marking solutions Hylax Technology Laser Solution Provider

. Eine zunehmend populäre Technologie zur Herstellung einer dauerhaften, direkten UDIProduktkennzeichnung ist das Laser markierungsverfahren, das auch als Laserglühen bezeichnet wird [5, 6]..

What is Laser Marking and How Does it Work? TechRound

Laser Handbook A comprehensive guide to industrial laser applications The many possible applications of the fiber laser The following overview indicates which materials can be processed using a fiber laser. Metals Processes

How Laser Marking Works Find The Optimal Method For Your Projects

PDF | On Jul 20, 2014, F. Hamadi and others published Contribution to laser marking parameters optimization | Find, read and cite all the research you need on ResearchGate

Catalog and PDF version of UV laser marking machine by Maven laser

Laser marking is a technique used frequently in the packaging and materials handling industries to form an indelible identification. The technique adopts a process of ink removal by overwriting an already printed surface using a focused laser beam.

(PDF) A comparison of Laser engraving machine,Laser marking machine and

The laser marks (ablates, melts, vaporizes, or removes) materials using a fine spot diameter which ranges from 0.002 in-0.01 in. It marks with short pulses (30 nano-seconds), providing precise mark control and negligible heat input. Subsequently, mark penetration into the material of less than 0.001 in unless otherwise required.

Laser Markings A Brief Overview WorthvieW

The LP-RV can generate a short pulse laser beam with a high repetition rate even if the scanning is performed at a higher speed. As a result, the laser marking is possible without spaces between dots irradiated by the laser, as shown in the left figure. This also shortens the laser marking or processing cycle time and improves the quality.

3Axis Fiber Laser Marker MDF series KEYENCE America

4. Lasers in laser marking 4.1 Laser resonator and modes 4.2 CO2 lasers 4.3 Nd:YAG lasers 4.4 Excimer lasers 4.5 Laser marking system evaluation 5. Major components & calculation in laser marking 5.1 Q-switch element 5.2 Beam expander 5.3 F-θ lens 5.4 Beam homogeniser 6. Laser marking mechanism and quality characteristics

Bringing Advanced Precision To Laser Marking Systems Smart World

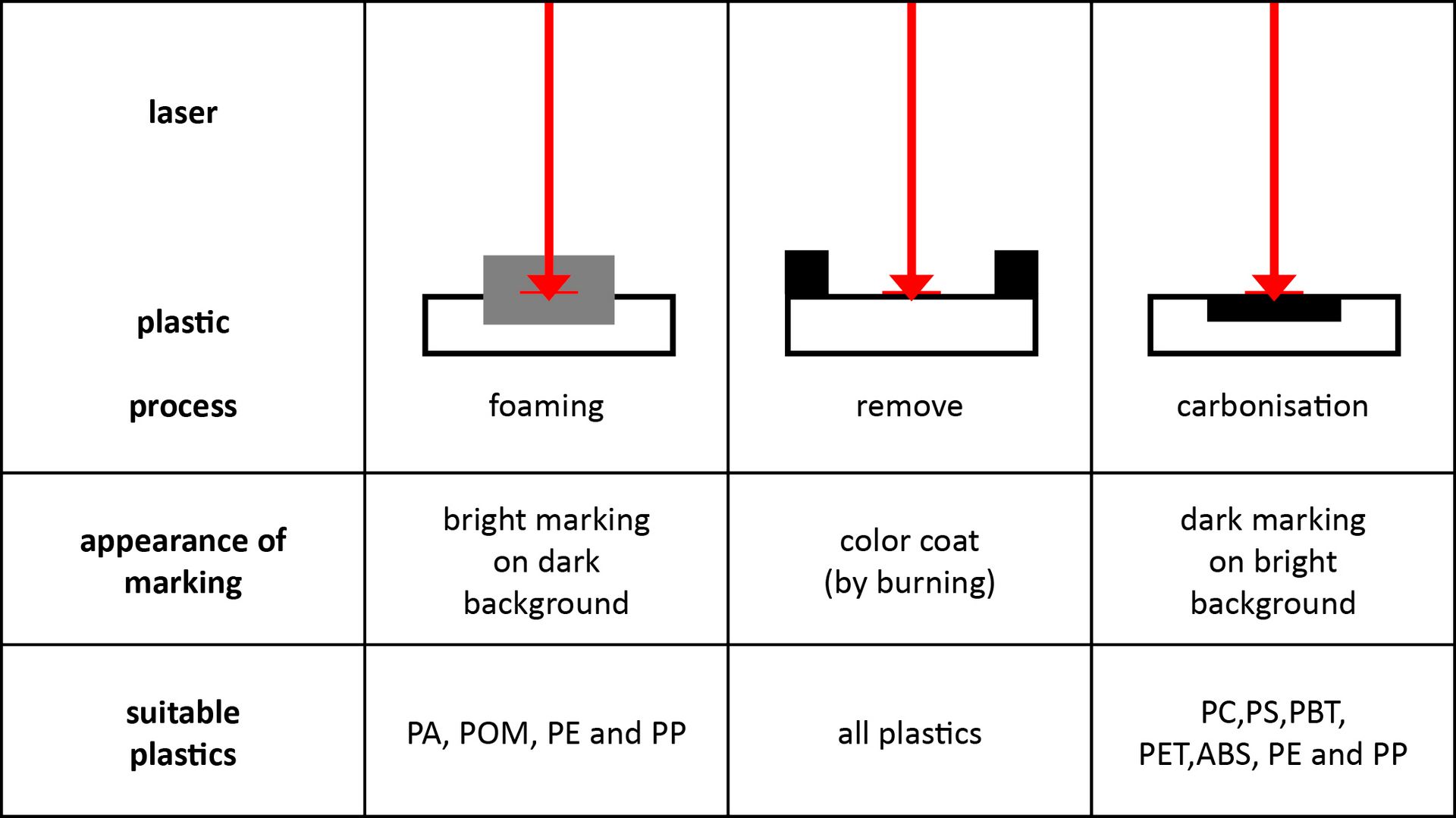

Laser Marking additives can provide high levels of contrast and shading. These formulations achieve line detail at impressive speeds on plastics that have historically been difficult to laser mark. Designed for thermal chemical surface reactions, these formulations are ideal for fiber, YAG, and vanadate lasers operating at a.